Description

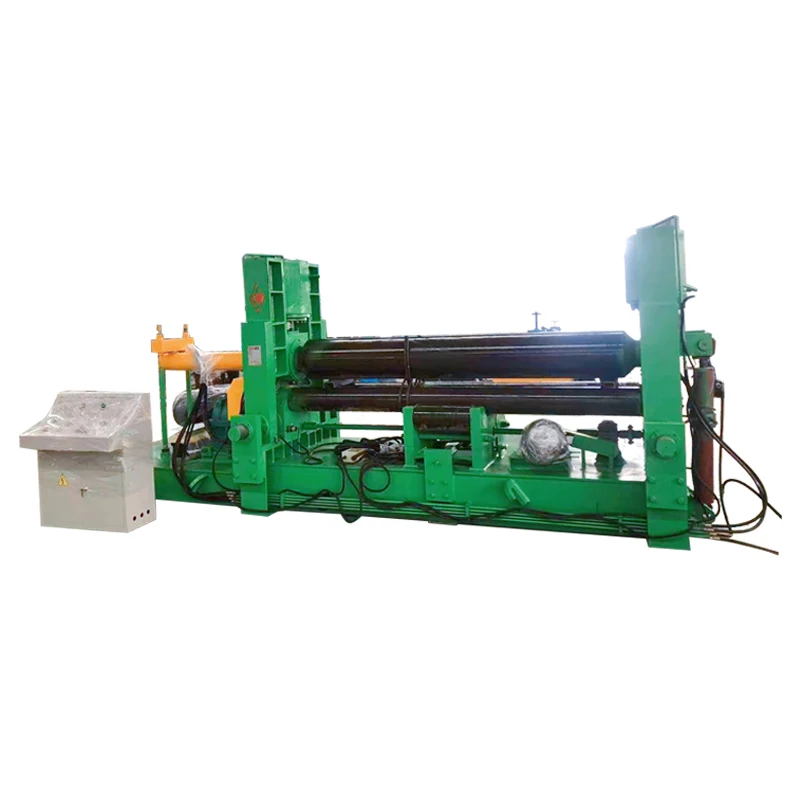

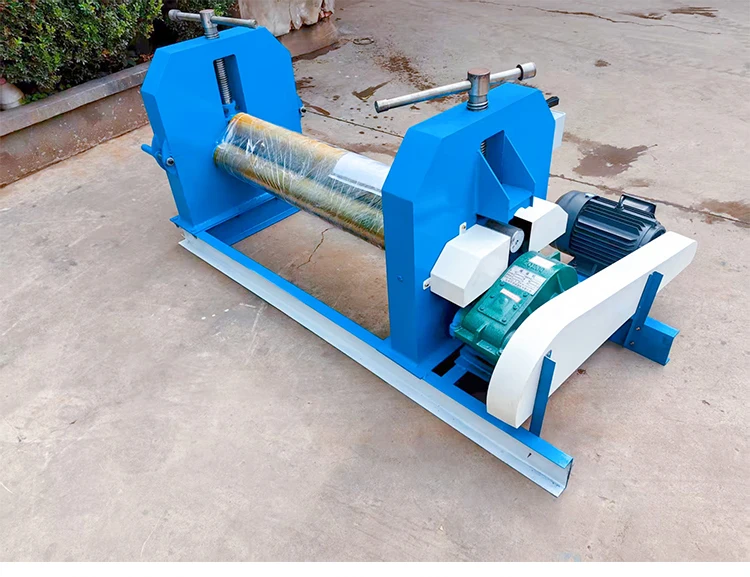

The manual lifting plate bending machine is a small-to-medium-sized equipment that relies on manual operation to adjust the lifting of rollers. specifically designed for the rolling processing of metal plates. It is widely used in small-batch. simple circular rolling scenarios

Structural Features It adopts a simple two-roller or three-roller structure as a whole (with the three-roller type being the main one). mainly composed of components such as a frame. manual adjustment mechanisms (e.g.. handwheels. lead screws). rollers. and transmission gears.- Without a complex electronic control system. it relies on manual rotation of handwheels to drive lead screw transmission. realizing the lifting of the upper roller or side rollers. The adjustment process is intuitive and controllable. The equipment is small in size and light in weight. facilitating transportation and flexible site layout.- The rollers are mostly made of 45# steel or high-quality alloy steel. processed through technologies such as quenching and tempering. and quenching. They have high surface hardness and strong wear resistance. which can meet the rolling needs of conventional metal plates.

Working Principle During operation. first. rotate the lifting handwheel manually to adjust the distance between the upper roller and lower roller (determined by the thickness of the plate). and place the flat metal plate between the two rollers (or three rollers);- After starting the equipment. the lower roller (driving roller) rotates driven by a motor or manually to drive the plate for feeding; at the same time. according to the required rolling arc. continuously fine-tune the height of the upper roller/side rollers manually. By utilizing the friction and extrusion between the rollers and the plate. the flat plate is gradually bent into arc-shaped. semicircular. or cylindrical workpieces.

Performance and Operational Characteristics – Low operation threshold

No professional electronic control programming knowledge

is required. Operators can quickly get started by familiarizing themselves with the handwheel adjustment range and roller speed

(some models have manually adjustable speed). making it suitable for small processing plants or individual workshops. – Limited

rolling range: It is mainly suitable for thin steel plates. aluminum plates. stainless steel plates. etc.. with a thickness of

0.3-3mm. The rolling diameter is usually between 50-500mm. and it is difficult to process thick plates or large-diameter

workpieces. Its processing accuracy is slightly lower than that of CNC models (the error is generally within ±1mm). – Safety and

maintenance: Since there is no automatic lifting protection device. operators need to manually control the adjustment force during

operation to avoid roller deformation caused by overload; daily maintenance is simple. only requiring regular lubrication of

transmission parts such as lead screws and gears. and cleaning of impurities on the roller surface

is required. Operators can quickly get started by familiarizing themselves with the handwheel adjustment range and roller speed

(some models have manually adjustable speed). making it suitable for small processing plants or individual workshops. – Limited

rolling range: It is mainly suitable for thin steel plates. aluminum plates. stainless steel plates. etc.. with a thickness of

0.3-3mm. The rolling diameter is usually between 50-500mm. and it is difficult to process thick plates or large-diameter

workpieces. Its processing accuracy is slightly lower than that of CNC models (the error is generally within ±1mm). – Safety and

maintenance: Since there is no automatic lifting protection device. operators need to manually control the adjustment force during

operation to avoid roller deformation caused by overload; daily maintenance is simple. only requiring regular lubrication of

transmission parts such as lead screws and gears. and cleaning of impurities on the roller surface

Application Scenarios Industry fields: Suitable for scenarios with low precision requirements. such as ventilation duct production. hardware accessory processing. pre-bending of small pressure vessel heads. and decoration projects (e.g.. arc-shaped metal parts).- Production needs: More suitable for flexible processing of small batches and multiple specifications. or as an auxiliary equipment for large plate bending machines to perform pre-bending or supplementary processing of small workpieces. It is not suitable for large-scale. high-precision automated production lines.

Products Description

item | value |

WWType | W11-6*1600 |

Upper rod diameter(mm) | 159 |

Lower rod diameter (mm) | 140 |

Material / metal processed | Carbon Steel. STAINLESS STEEL. aluminum |

Weight (kg) | 450 |

Dimension(mm) | 2400*750*950 |

Minimum diameter of coiling (mm) | 200 |

Warranty | 1 years |

Core components | Bearing. Gearbox. PLC. GEAR. MOTOR |

model (KW) | 4 |

reducer model | 250 |

Place of origin | China |

Brand name | Jetamc |

Automation | Manual |

Key selling points | High Safety Level |

1. who are we?

We are based in Anhui. China. start from 2025.sell to Oceania(10.00%).Africa(10.00%).Southeast Asia(10.00%).Eastern

Europe(10.00%).South America(10.00%).South Asia(10.00%).North America(10.00%).Mid East(5.00%).Domestic Market(5.00%).Northern

Europe(5.00%).Central America(5.00%).Western Europe(5.00%).Eastern Asia(5.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

press brake.Shearing Machine.rolling machine

4. why should you buy from us not from other suppliers?

The registered address of the enterprise is located at No. 2. Building 1. Jinye Huayuan. Bowa Town. B District. Ma'anshan City.

Anhui Province. The industry it belongs to is wholesale trade. and the business scope includes: general items: import and export

5. what services can we provide?

Accepted Delivery Terms: FOB.CFR.CIF.EXW;

Accepted Payment Currency: USD.CNY;

Accepted Payment Type: T/T.L/C;

Language Spoken: English.Chinese.Spanish.Japanese.Portuguese.German.Arabic.French.Russian.Korean.Hindi.Italian

We are based in Anhui. China. start from 2025.sell to Oceania(10.00%).Africa(10.00%).Southeast Asia(10.00%).Eastern

Europe(10.00%).South America(10.00%).South Asia(10.00%).North America(10.00%).Mid East(5.00%).Domestic Market(5.00%).Northern

Europe(5.00%).Central America(5.00%).Western Europe(5.00%).Eastern Asia(5.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

press brake.Shearing Machine.rolling machine

4. why should you buy from us not from other suppliers?

The registered address of the enterprise is located at No. 2. Building 1. Jinye Huayuan. Bowa Town. B District. Ma'anshan City.

Anhui Province. The industry it belongs to is wholesale trade. and the business scope includes: general items: import and export

5. what services can we provide?

Accepted Delivery Terms: FOB.CFR.CIF.EXW;

Accepted Payment Currency: USD.CNY;

Accepted Payment Type: T/T.L/C;

Language Spoken: English.Chinese.Spanish.Japanese.Portuguese.German.Arabic.French.Russian.Korean.Hindi.Italian

Small Electric Reel Manual Plate Rolling Bending Three-Roller for Iron Stainless Steel PVC Aluminum for Metal Processing

CURABITUR ALIQUET QUAM POSUERE

DO YOU LIKE THE THEME? SHARE WITH YOUR FRIENDS!

Will be used in accordance with our Privacy Policy