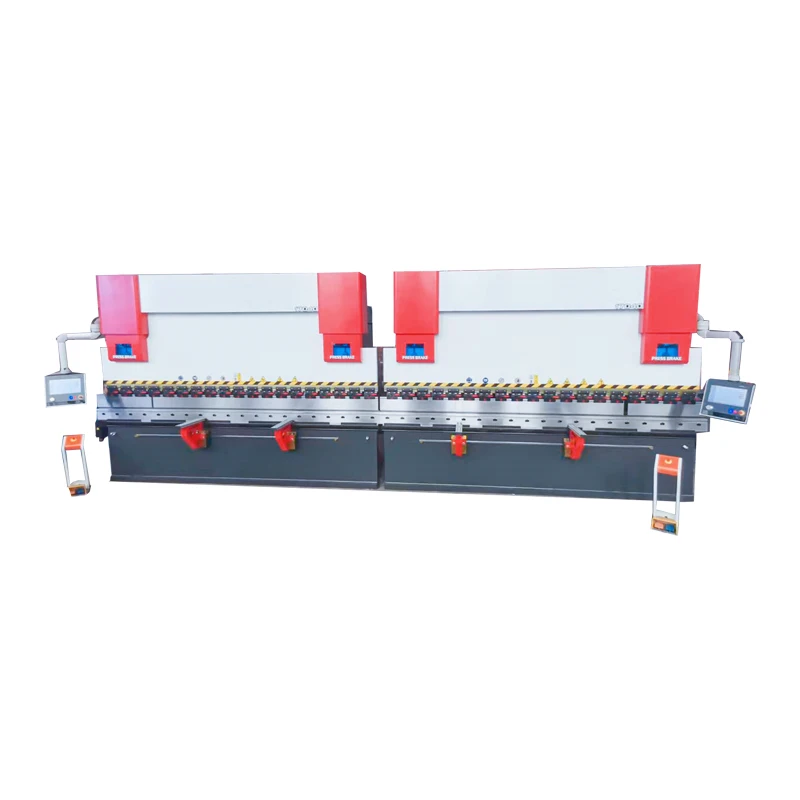

Description

Dual-machine linkage of electro-hydraulic bending machines refers to a technical solution that realizes synchronous and coordinated control of two electro-hydraulic bending machines with matched specifications through a dedicated control system. forming an "integrated bending unit". Its core is to meet the bending needs of extra-wide and extra-long metal plates (such as steel plates and aluminum alloy plates with a length of 8m-20m) that cannot be processed by a single bending machine. while ensuring the consistency and precision of the bending angle of extra-wide workpieces. It is widely used in the manufacturing field of heavy or large structural parts such as wind power tower drums. container side panels. large pressure vessel shells. and rail transit car bodies.

Core CompositionTwo Matched Electro-Hydraulic Bending Machines: Electro-hydraulic bending machines of the same model and specification (e.g.. basic models with the same nominal pressure and same bending length) must be selected to ensure consistent hardware performance. laying a foundation for synchronous linkage. In some scenarios. customized machines with a "master-slave" configuration can be selected according to workpiece requirements (the master machine is equipped with a core control module. and the slave machine serves as a cooperative execution module).- Dedicated Linkage Control System: Equipped with a numerical control system supporting dual-machine communication (such as DA66T-L. Cybelec DNC8800. etc.). it realizes real-time data interaction between the two machines through industrial Ethernet (such as Profinet. EtherCAT). The transmission delay of control signals is usually ≤ 10ms to ensure action synchronization.- Synchronization Detection and Compensation Module: It includes a linear scale (to detect the slider displacement of the two machines). a pressure sensor (to monitor the bending force). and an angle encoder (to feed back the bending angle). which collects the operation data of the two machines in real time. If a displacement deviation occurs (such as asynchronous slider lifting/lowering or inconsistent bending angles). the system will automatically output a compensation signal to adjust the action of one-side machine and correct the deviation.- Tooling and Positioning Auxiliary Devices: Including a shared extra-wide workbench. a synchronous feeding mechanism (such as a roller conveyor). and workpiece positioning fixtures. These devices ensure that extra-wide plates are placed stably and positioned accurately during the bending process. avoiding the impact of plate deviation on linkage precision.

Linkage Working Principle1. Parameter Setting and Programming: Through the unified operation interface of the linkage control system. the operator inputs the bending parameters of the extra-wide workpiece (such as bending angle. bending depth. plate thickness. and plate material). The system automatically distributes the parameters to the two bending machines and generates a cooperative bending program.2. Synchronous Startup and Action Coordination: After starting the machines. the control system sends action commands to the two bending machines simultaneously. driving the sliders of the two machines to lift/lower synchronously and the workbenches to adjust synchronously. During the bending process. the synchronization detection module collects the slider position and bending force data of the two machines in real time. and the data is fed back to the main control system through the communication link.3. Real-Time Deviation Compensation: If the main control system detects a displacement deviation (e.g.. one slider is 0.1mm higher than the other) or a bending force difference between the two machines. it will immediately send a compensation command to the machine with deviation. fine-tune the opening of its hydraulic valve or the motor speed. and re-synchronize the actions of both sides to ensure consistent bending angles and depths on both sides of the extra-wide plate.4. Process Completion and Reset: After the completion of a single bending process. the sliders of the two machines reset synchronously. The feeding mechanism conveys the workpiece to the next bending station. and the above cooperative process is repeated until the bending of the entire extra-wide workpiece is completed.

Products Description

Core Advantages1. Breaking Through Processing Size Limitations: The maximum bending length of a single electro-hydraulic bending machine is usually ≤ 6m. while dual-machine linkage can realize the bending of extra-wide plates with a length of 8m-20m. It solves the pain point that large structural parts "cannot be bent as a whole" and avoids precision errors caused by splicing after segmental bending of workpieces.2. High Synchronization Precision and Bending Quality: Through real-time detection and automatic compensation. the slider synchronization precision of dual-machine linkage can reach ±0.05mm. and the consistency error of bending angles is ≤ 0.5°. which is far better than the processing precision of manually coordinated two machines. It ensures that there are no problems such as "side bending" and "angle deviation" after the integral bending forming of extra-wide workpieces.3. Improving Processing Efficiency and Safety: Compared with the traditional process of "segmental bending + splicing". dual-machine linkage can realize "one-time bending forming" of extra-wide workpieces. improving processing efficiency by 30%-50%. At the same time. the workpiece does not need to be handled or flipped multiple times. reducing manual intervention and lowering the safety risks during the handling of large plates.4. Flexible Adaptation to Multi-Scenario Requirements: The linkage system supports two modes: "dual-machine synchronous bending" and "one-side independent bending" (subject to workpiece adaptation). When processing plates of conventional width. the linkage can be disconnected. and the two machines can be restored to independent operation. improving equipment utilization and adapting to the production needs of workpieces of different specifications.

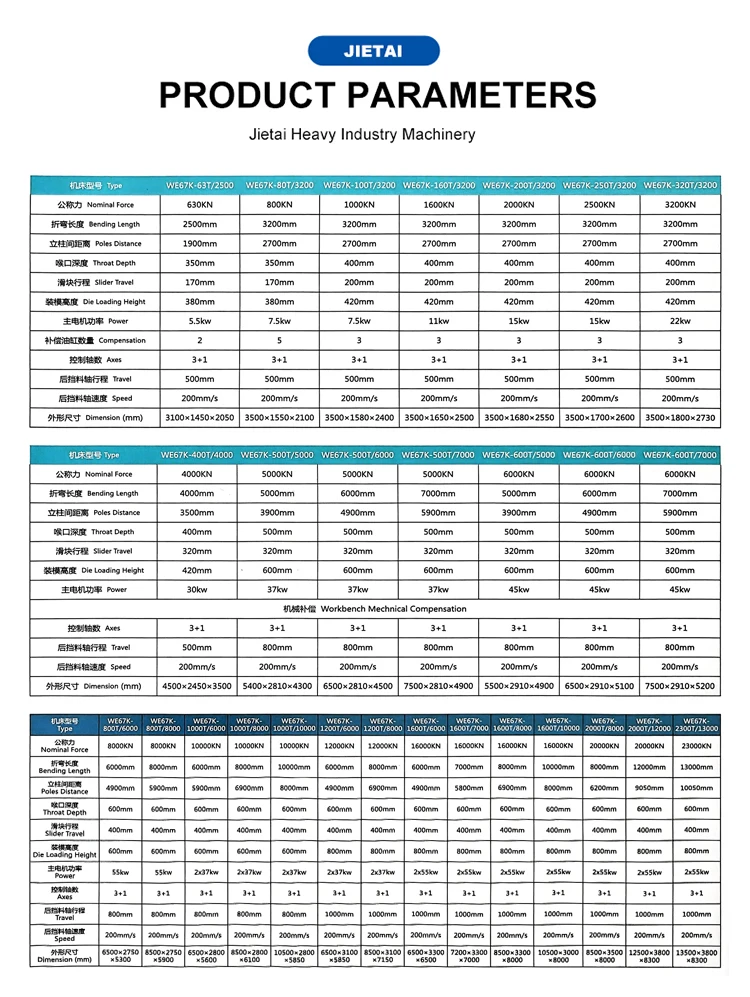

item | value |

Bending force (KN) | 3400 |

Length of working table (mm) | 8000 |

Automatic level | Fully Automatic |

Material / metal processed | Carbon Steel. STAINLESS STEEL. aluminum |

Weight (kg) | 18000 |

Dimension(mm) | 8300*1800*2500 |

Warranty | 1 years |

Core components | Bearing. Gearbox. PLC. GEAR. MOTOR |

Slider stroke (mm) | 150 |

Throat depth (mm) | 360 |

Place of origin | China |

Brand name | Jetamc |

Automation | Automatic |

Key selling points | High-accuracy |

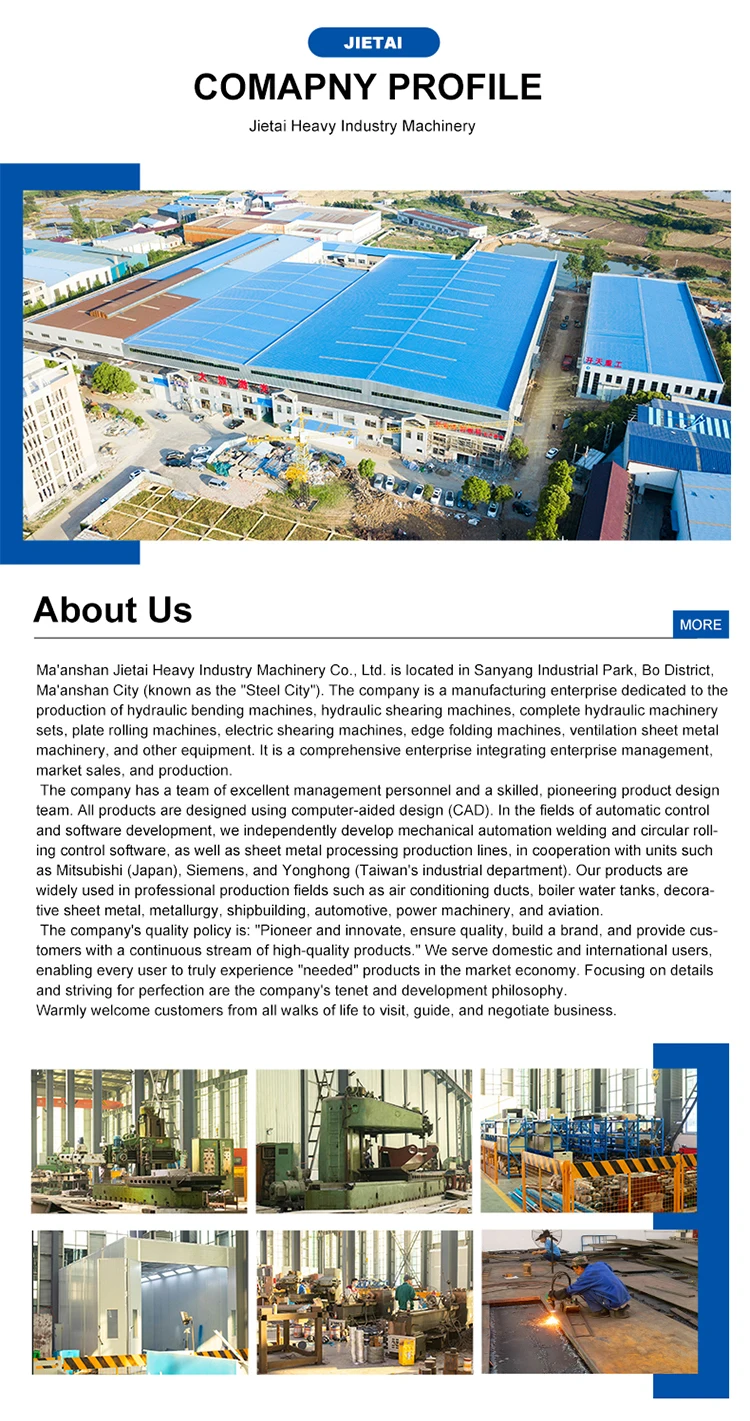

1. who are we?

We are based in Anhui. China. start from 2025.sell to Oceania(10.00%).Africa(10.00%).Southeast Asia(10.00%).Eastern

Europe(10.00%).South America(10.00%).South Asia(10.00%).North America(10.00%).Mid East(5.00%).Domestic Market(5.00%).Northern

Europe(5.00%).Central America(5.00%).Western Europe(5.00%).Eastern Asia(5.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

press brake.Shearing Machine.rolling machine

4. why should you buy from us not from other suppliers?

The registered address of the enterprise is located at No. 2. Building 1. Jinye Huayuan. Bowa Town. B District. Ma'anshan City.

Anhui Province. The industry it belongs to is wholesale trade. and the business scope includes: general items: import and export

5. what services can we provide?

Accepted Delivery Terms: FOB.CFR.CIF.EXW;

Accepted Payment Currency: USD.CNY;

Accepted Payment Type: T/T.L/C;

Language Spoken: English.Chinese.Spanish.Japanese.Portuguese.German.Arabic.French.Russian.Korean.Hindi.Italian

We are based in Anhui. China. start from 2025.sell to Oceania(10.00%).Africa(10.00%).Southeast Asia(10.00%).Eastern

Europe(10.00%).South America(10.00%).South Asia(10.00%).North America(10.00%).Mid East(5.00%).Domestic Market(5.00%).Northern

Europe(5.00%).Central America(5.00%).Western Europe(5.00%).Eastern Asia(5.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

press brake.Shearing Machine.rolling machine

4. why should you buy from us not from other suppliers?

The registered address of the enterprise is located at No. 2. Building 1. Jinye Huayuan. Bowa Town. B District. Ma'anshan City.

Anhui Province. The industry it belongs to is wholesale trade. and the business scope includes: general items: import and export

5. what services can we provide?

Accepted Delivery Terms: FOB.CFR.CIF.EXW;

Accepted Payment Currency: USD.CNY;

Accepted Payment Type: T/T.L/C;

Language Spoken: English.Chinese.Spanish.Japanese.Portuguese.German.Arabic.French.Russian.Korean.Hindi.Italian

High-Precision CNC Control System Automatic Hydraulic Press Brake Double-Machine Linkage for Aluminum Pump Bearing Gear

CURABITUR ALIQUET QUAM POSUERE

DO YOU LIKE THE THEME? SHARE WITH YOUR FRIENDS!

Will be used in accordance with our Privacy Policy