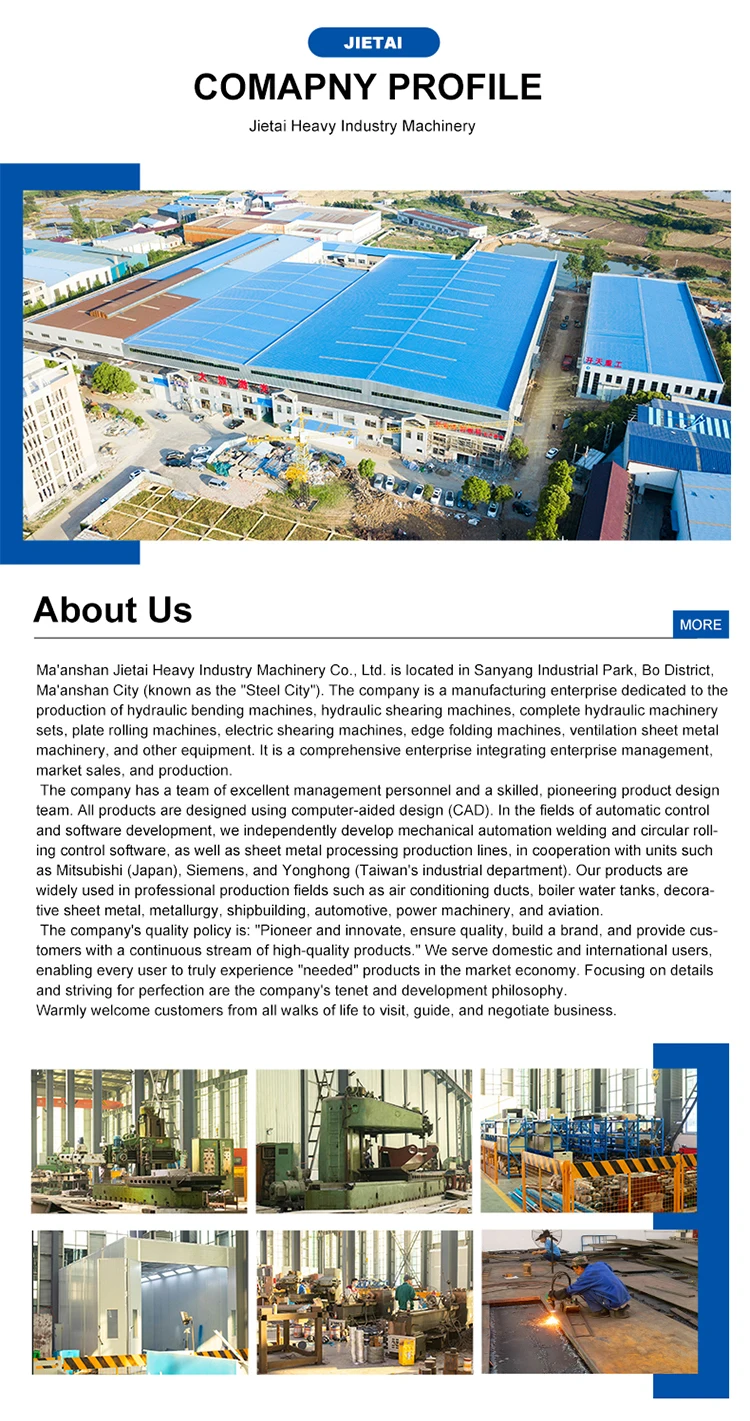

About Us

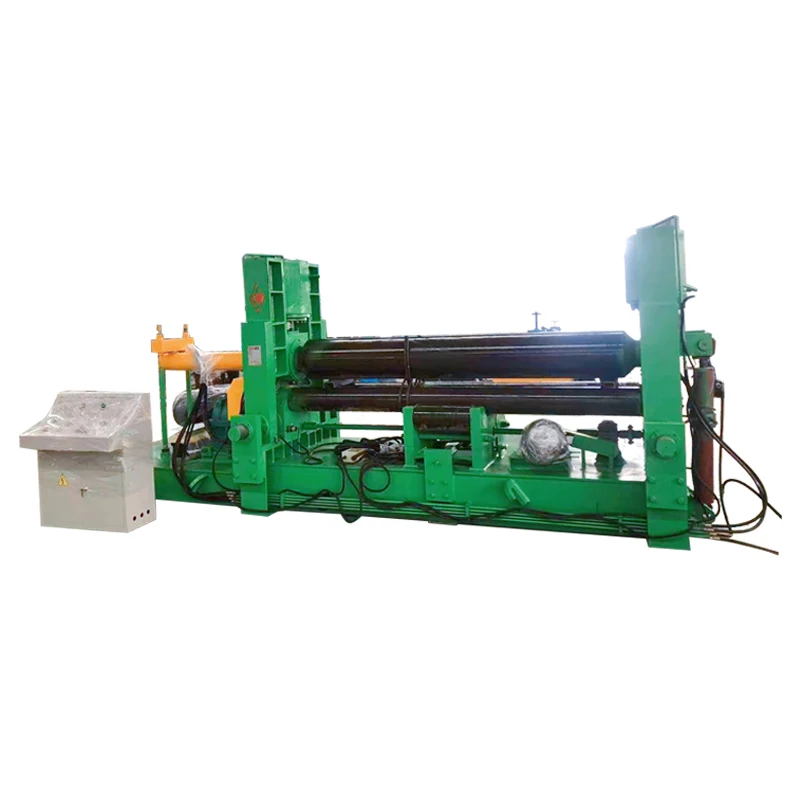

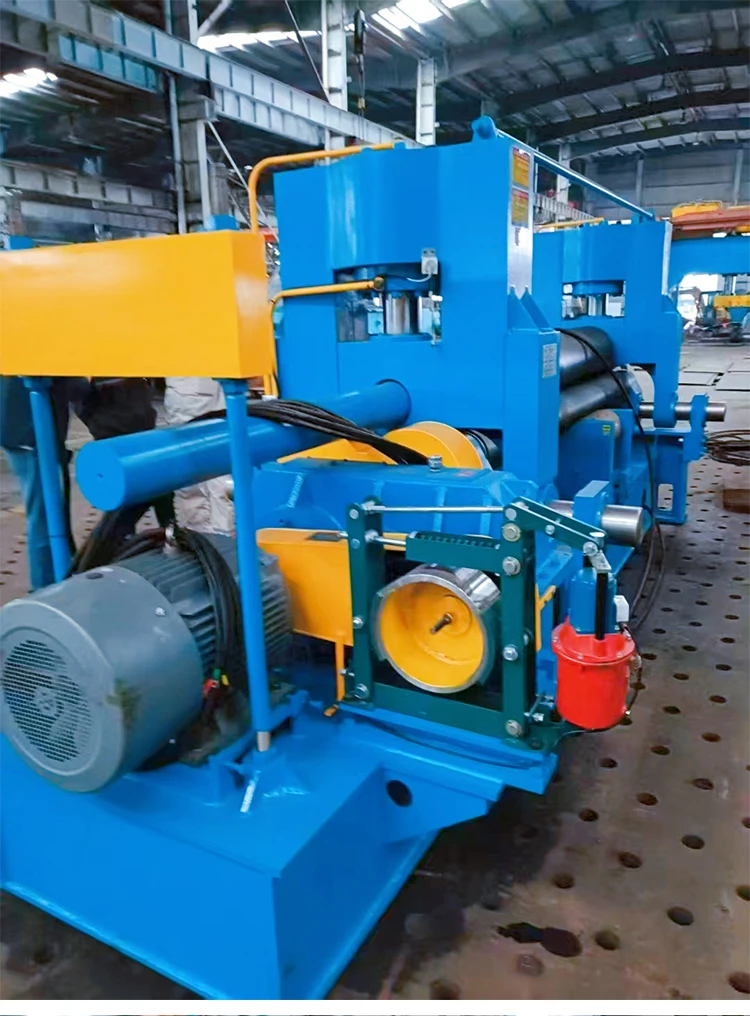

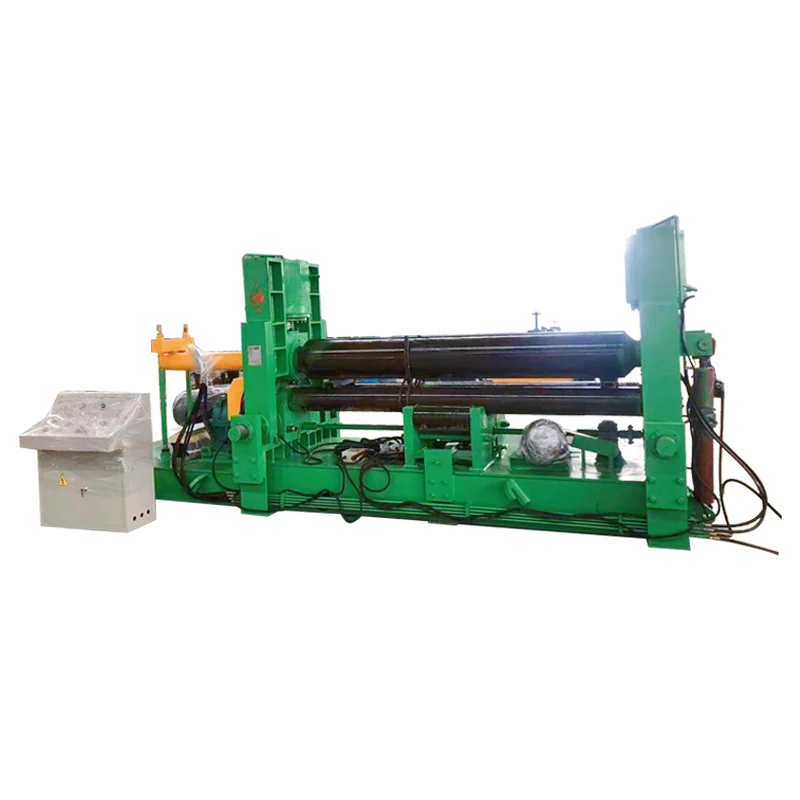

Maanshan Jietai Import and Export Trading Co., Ltd., located in the Industrial Park of Bowang District, Maanshan City, Anhui Province, is a professional company specializing in the retail and wholesale of hydraulic CNC bending machines, hydraulic CNC shearing machines, laser cutting machines, plate rolling machines, combined punching and shearing machines, and ventilation duct equipment.

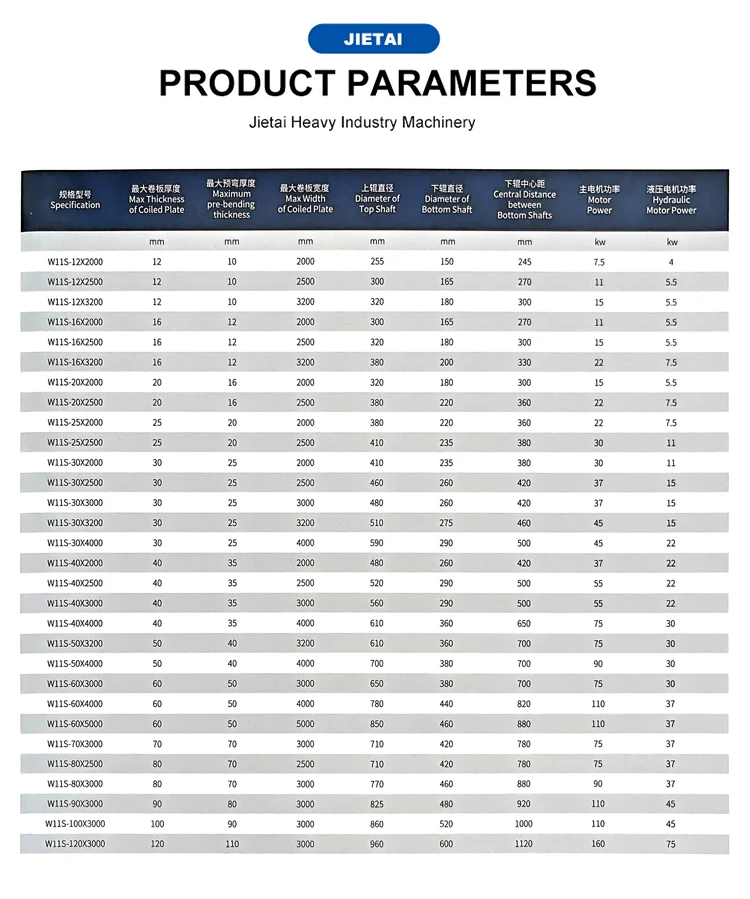

The company’s main products include: CNC torsion axis hydraulic bending machines, electro-hydraulic CNC hydraulic bending machines, hydraulic swing shearing machines, hydraulic gate-type shearing machines, three-axis plate rolling machines, CNC four-axis plate rolling machines, ventilation duct equipment, etc. Meanwhile, it can provide customers with one-stop import and export agency, customs declaration and inspection, logistics and transportation and other full-process services.

Contact

Contact Us

For technical inquiries about our products, solutions, and other specific matters, please fill out the form below and click the “Submit” button. We will contact you as soon as possible.